Assessing Production Stability in Your Supply Chain

페이지 정보

작성자 Hollie 댓글 0건 조회 20회 작성일 25-09-20 00:49본문

Stability in your supply chain’s manufacturing operations is vital for on-time delivery, cost efficiency, and minimizing unexpected interruptions

Businesses often chase efficiency and reduced overhead, ignoring how vital uniformity in production truly is

With a reliable supply chain, raw inputs reach you punctually, production lines operate without hiccups, and finished goods reach customers free from surprises or defects

Begin your evaluation by analyzing how your suppliers have performed across recent months or quarters

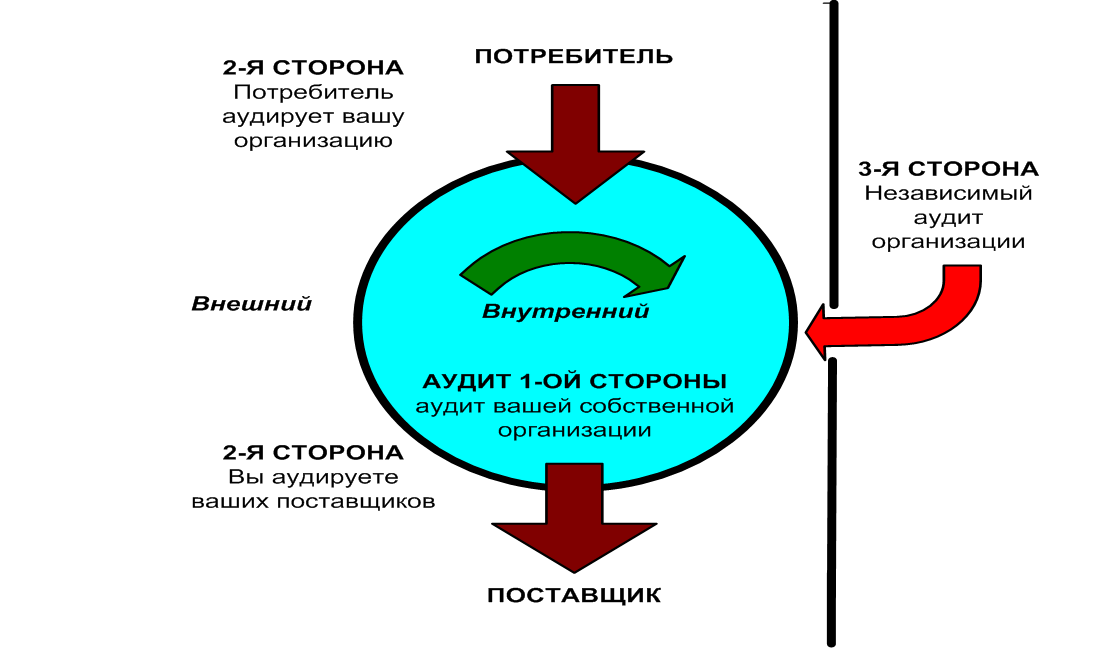

Look at on time delivery rates, аудит поставщика defect rates, and communication responsiveness

If certain suppliers consistently miss deadlines or deliver substandard materials, it’s a sign that your supply chain is vulnerable

Track these metrics monthly and set clear benchmarks

A vendor hitting 95% of goals consistently is vastly more dependable than one whose performance swings wildly from 70% to 95%

Next, examine your internal production processes

Are equipment breakdowns common? Are there recurring congestion points in your assembly lines? Is training standardized and are tools properly maintained and distributed?

Instability often comes from within

Conduct regular audits of your production lines and gather feedback from frontline staff

Frontline employees frequently detect early warning signs that management might miss

Inventory strategy plays a pivotal role in maintaining stability

Too little inventory can cause production halts when materials are delayed

Excess inventory drains financial resources and increases the risk of obsolescence or spoilage

Base your inventory decisions on trend analysis and predictive modeling rather than guesswork

Maintain buffer stocks for essential parts and identify backup vendors for materials prone to disruption

Without clear, end-to-end visibility, you’re operating in the dark

Not knowing the location or status of your inputs means you’re reacting instead of planning

Deploy integrated systems that deliver instant notifications on shipment progress, delays, and inventory levels

Immediate visibility empowers swift, informed responses to emerging supply chain disruptions

Beyond systems and data, human trust is the foundation of resilience

Reliability is built as much on loyalty and communication as it is on KPIs and dashboards

Schedule consistent check-ins, encourage transparent dialogue, and align on mutual success metrics

In times of crisis, partners you’ve nurtured will prioritize your needs over those of competitors

Achieving supply chain stability is never a one-time achievement—it’s an ongoing discipline

Maintaining stability means choosing long-term resilience over short-lived cost reductions or accelerated timelines

By evaluating your suppliers, refining your processes, managing inventory wisely, improving visibility, and nurturing partnerships, you create a supply chain that can withstand fluctuations and continue delivering value to your customers

댓글목록

등록된 댓글이 없습니다.