Optimizing Ink Performance by Analyzing Pigment Particle Geometry

페이지 정보

작성자 Shaun 댓글 0건 조회 5회 작성일 25-12-31 16:10본문

Achieving consistent ink formulation is a critical challenge in industries ranging from printing and packaging to electronics and cosmetics

The geometry of pigment and additive particles, frequently neglected, plays a decisive role in ink behavior

Although particle size has traditionally dominated quality assurance protocols, particle shape—spherical, elongated, plate-like, or irregular—equally governs rheology, chromatic depth, suspension stability, and printed output quality

By incorporating advanced particle shape analysis into the formulation process, manufacturers can achieve unprecedented levels of consistency and reliability in their ink products

Traditional methods of ink development have relied heavily on trial and error, adjusting pigment concentrations, solvent ratios, and dispersants without a full understanding of how particle morphology affects the system

However, modern imaging and computational techniques now allow for precise characterization of particle shapes in three dimensions

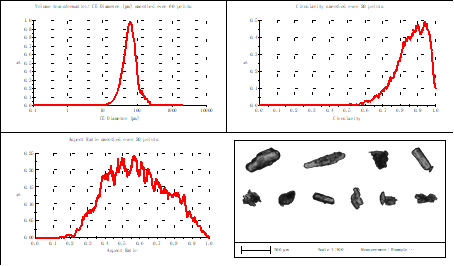

Methods including high-speed particle imaging, shape-sensitive laser scattering, and SEM-based automated feature extraction yield precise measurements of elongation, roundness, roughness, and aspect ratio

These metrics reveal how particles aggregate, settle, or align under shear forces during mixing and application

Particles with near-perfect roundness exhibit superior suspension stability and fluid homogeneity, making them best suited for high-throughput printing systems

Platelet morphologies improve opacity and surface luster by stacking in parallel planes during film formation, but can result in metamerism when viewed from oblique angles

Elongated particles contribute to film toughness, but uncontrolled aspect ratios between production runs can destabilize viscosity and compromise print consistency

Understanding these relationships allows formulators to select or engineer particles with ideal geometries for specific end uses

Maintaining consistent particle morphology is essential for preventing instability in ink dispersions

Irregularly shaped particles have higher surface energy and 粒子形状測定 more points of contact, which can lead to increased agglomeration

Such agglomeration manifests as patchy coloration, blurred print detail, and frequent nozzle blockages in inkjet devices

Tracking shape variability through time-series analysis allows manufacturers to preemptively recalibrate milling duration, dispersant chemistry, or shear rates to sustain target morphology

Growing ecological and compliance demands are pushing manufacturers toward greener, resource-efficient ink designs

Shape analysis enables the use of fewer materials by optimizing the efficiency of each particle

A well-shaped pigment can deliver the same color strength with lower loading, reducing raw material costs and environmental impact

Shape analysis is critical for advancing water-based and solvent-free inks, as their unique drying kinetics and reduced surface tension make them particularly responsive to particle morphology

Adopting morphological analysis demands upfront costs in equipment and expertise, yet delivers significant long-term gains

Consistent shape profiles decrease reject rates, shorten changeover times, and elevate overall customer experience

Product development cycles shorten as engineers shift from trial-and-error tactics to evidence-based particle design principles

In summary, improving ink formulation consistency through particle shape analysis represents a paradigm shift from reactive problem solving to predictive formulation science

By elevating particle shape to the same strategic level as size and chemical composition, producers gain deeper command over ink behavior, longevity, and consistency

As analytical capabilities mature, particle shape characterization will transition from a premium tool to an indispensable pillar of international ink quality assurance

댓글목록

등록된 댓글이 없습니다.