Imaging-Based Real-Time Control Systems for Modern Manufacturing

페이지 정보

작성자 Eddy 댓글 0건 조회 4회 작성일 25-12-31 23:34본문

In modern industrial environments, the capacity for instantaneous process adaptation has become a non-negotiable requirement for competitive manufacturing. One of the most powerful tools enabling this capability is the integration of imaging data into real-time feedback loops for process control. By leveraging thermal imaging arrays, industrial cameras, AI-driven vision platforms, and deep learning-based analysis, manufacturers can now identify minute anomalies in real time and trigger immediate corrective actions.

Imaging systems capture both optical and infrared signatures across production phases. For example, in a metal forging operation, thermal cameras can monitor surface temperature distributions across components to ensure uniform heating. If a hotspot is detected that exceeds the acceptable range, the system immediately triggers an adjustment in the heating element’s power or the material’s movement speed. Similarly, in food processing, camera-based inspection units detect seal breaches, mislabeled items, or microbial traces. Any anomaly — even a microscopic flaw — is identified instantly, triggering quarantine protocols or bypass routing to prevent downstream contamination.

The real power of these systems lies not in mere detection, but in the seamless coupling of visual feedback with industrial actuators. Traditional quality control often relies on batch-based sampling and subjective evaluation, which introduces inherent latency and high failure exposure. In contrast, real-time feedback loops use ongoing video feeds to train and update adaptive control systems. These models, often powered by self-learning classifiers and anomaly detection engines, learn from historical patterns to anticipate issues before they escalate. For instance, a slight change in the texture of a polymer extrusion might indicate an impending clog; the system can preemptively increase pressure or alert maintenance personnel before a shutdown occurs.

The integration of distributed processing has further enhanced this capability. Instead of sending high-bandwidth footage to remote data centers, modern systems process images using ruggedized edge nodes. This minimizes delays, conserves network resources, and maintains functionality in harsh or intermittent network conditions. Combined with high-resolution sensors capable of capturing thousands of frames per second, the entire feedback cycle — data capture to corrective output — can occur in as fast as 30ms, perfect for precision-intensive operations such as microelectronics assembly or capsule dosing.

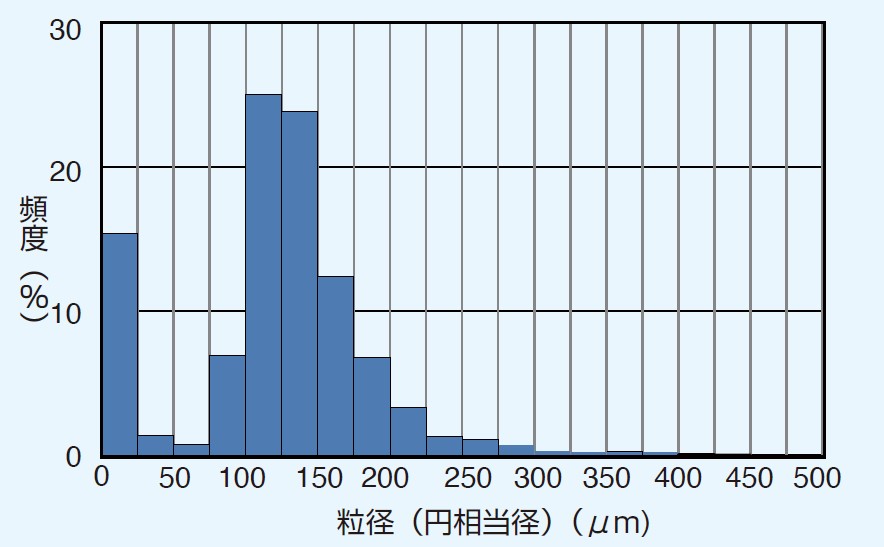

Moreover, the data generated by these imaging systems serves a dual purpose. Beyond immediate control, it creates a rich, time-stamped record of process conditions that can be used for failure diagnostics, regulatory documentation, 粒子形状測定 and process optimization. Supervisors can replay visual logs to understand how a particular defect emerged, and engineers can refine process parameters using data-driven insights rather than guesswork.

Implementing such systems requires strategic design. Sensor placement must be optimized to capture the most relevant features without interference from ambient light, vibration, or steam. Calibration must be performed periodically to ensure metrological integrity, and redundancy is often built in to ensure system uptime. Training operators to recognize anomaly patterns and execute corrective actions is also essential, as manual intervention is still needed for uncertain or critical exceptions.

As industries continue to pursue digital transformation and smart manufacturing targets, real-time feedback loops based on imaging data are no longer optional — they are foundational. They transform static observation into dynamic decision-making, reducing waste, improving consistency, and enabling unprecedented levels of precision. The convergence of visual sensing, predictive analytics, and automated machinery is reshaping how factories operate, turning every camera into a vigilant guardian of quality and efficiency.

댓글목록

등록된 댓글이 없습니다.