Filter presses Restoration Materials and Systems

페이지 정보

작성자 Elden 댓글 0건 조회 49회 작성일 25-04-01 01:27본문

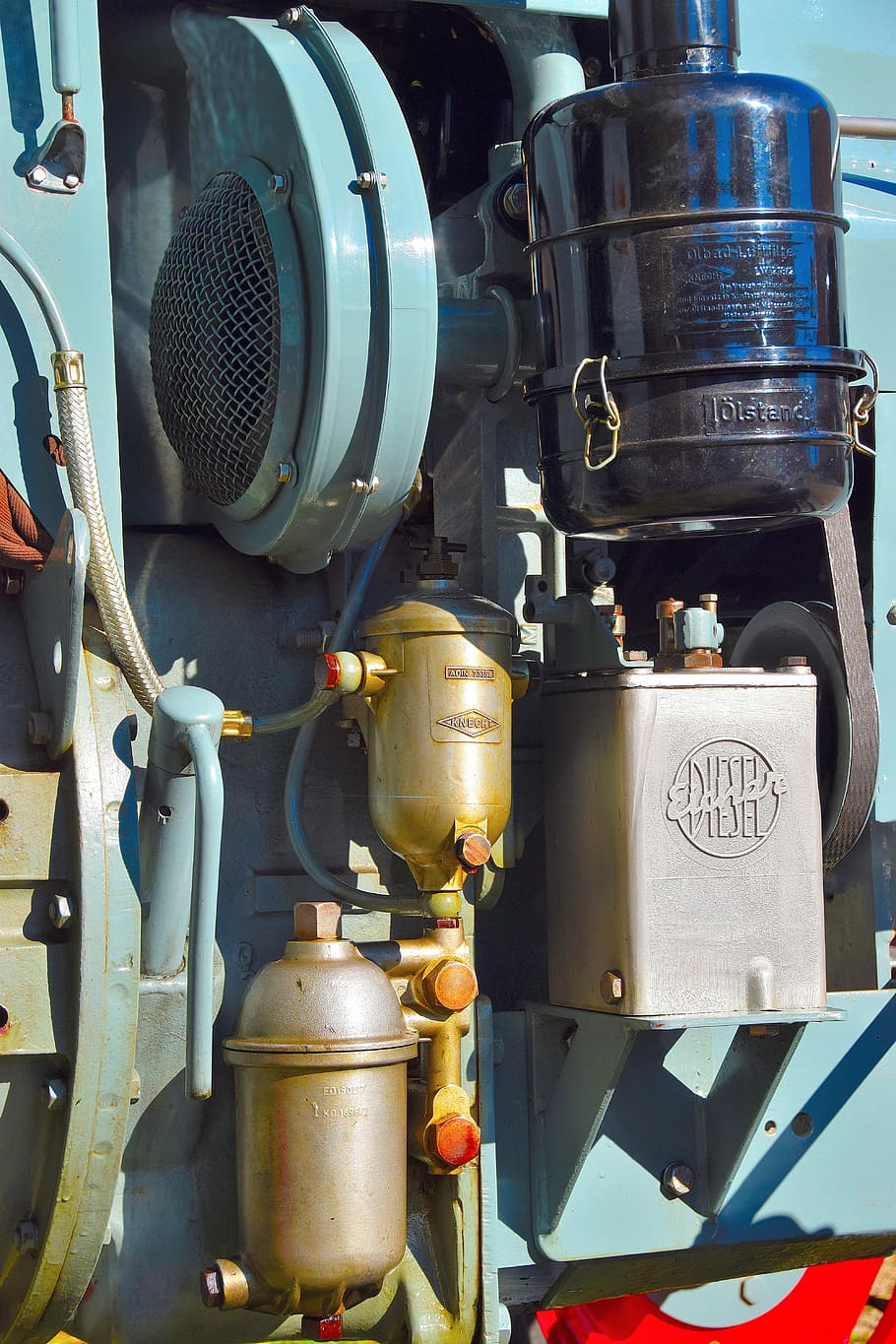

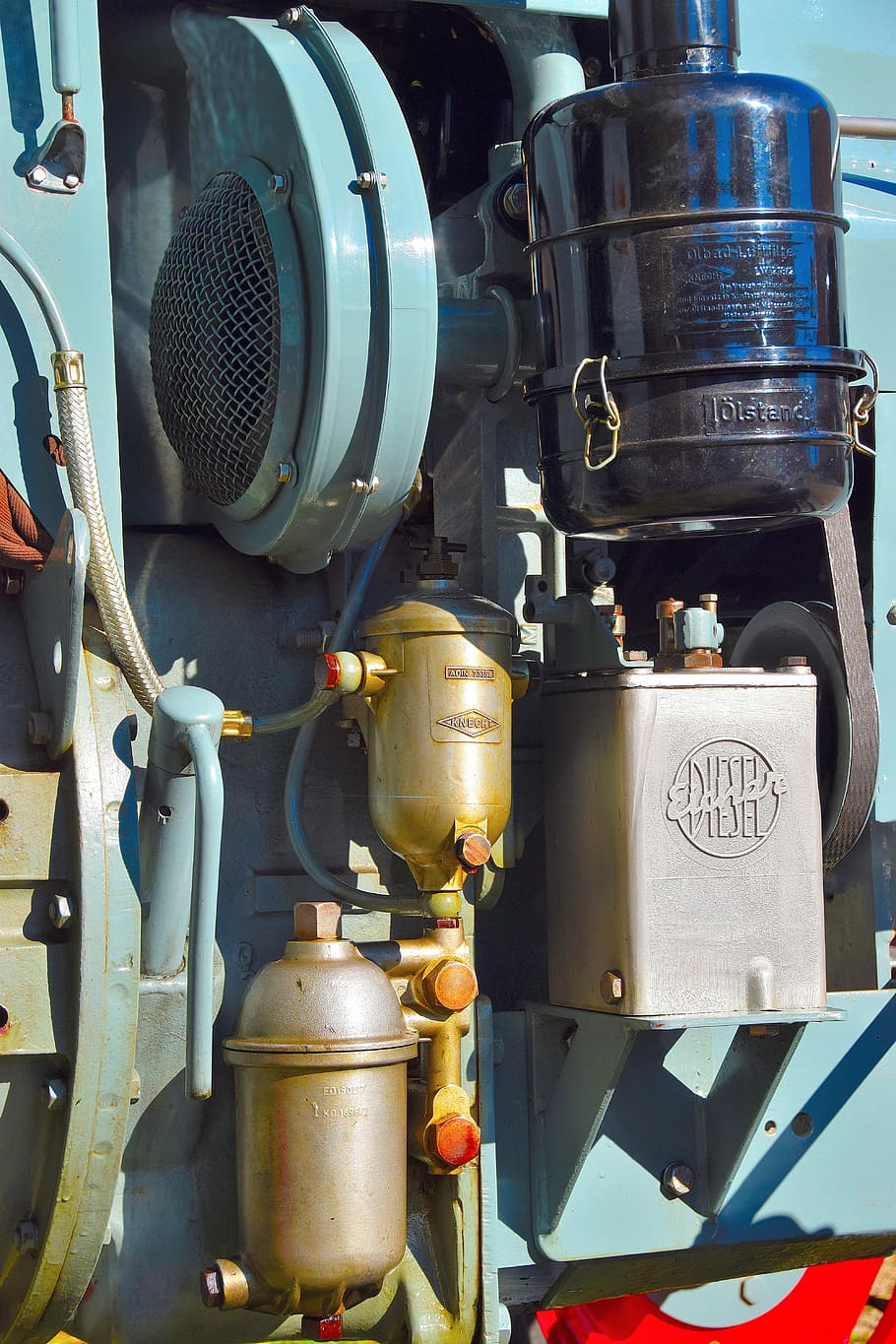

Press are commonly used in sectors like mining and production to isolates liquids from solids. However, as a result of the filtering process, equipment may get clogged with residues and dirt, leading to decreased efficiency and effectiveness. In order to keep and care for machines, expert chemicals and materials are.

Residue breaking down are often dissolve the hardened residue that occurs in the filtering process. Specific agents work by breaking down enabling easy removal of the machine.

Types of filter cake hardening contain lime.

Filter cake breaking down are often used as another common cleaning agent for filter presses. These special chemicals work to separate the filter cake enabling easy removal of the equipment. Examples of residue breaking down contain other chemicals that break down the ionic bonds binding particles.

Solutions for cleaning to clean equipment are designed with a blend of chemicals and materials designed to specific cleaning tasks. Such as a case a product may contain a mix of solvents, soap-like substances, and pH adjusters to completely remove oil and grease from the filter press plate and frame surfaces.

Alternative cleaning solutions hydrogen peroxide for bacterial and virus disinfection.

In order to choosing cleaning chemicals and materials for a equipment, several factors must be considered such as the kind of contaminants, equipment type, and machines employed. Various chemicals may be necessary for various contaminants or machines employed, so it's essential to consult the maker's guidelines for solutions.

In order to choosing cleaning chemicals and materials for a equipment, several factors must be considered such as the kind of contaminants, equipment type, and machines employed. Various chemicals may be necessary for various contaminants or machines employed, so it's essential to consult the maker's guidelines for solutions.

In addition to products, alternative equipment is required for maintaining and repairing equipment. Such as a case, sealants and gaskets are repeatedly applied to repair or replace damaged seals, preventing leakage and contamination.

Other important contain cleaning brushes, special cleaning agents, and drying cloths, which aid in take away hardened residue contaminants.

During winding up, renewing and repairing machines need specific products to ensure optimal performance and effectiveness. Cleaning the filter cake and different chemicals the proper choice of cleaning solutions, sealants, and maintenance parts, acknowledging the necessary conditions for machining cleaning is important for keeping a clean and efficient equipment.

Residue breaking down are often dissolve the hardened residue that occurs in the filtering process. Specific agents work by breaking down enabling easy removal of the machine.

Types of filter cake hardening contain lime.

Filter cake breaking down are often used as another common cleaning agent for filter presses. These special chemicals work to separate the filter cake enabling easy removal of the equipment. Examples of residue breaking down contain other chemicals that break down the ionic bonds binding particles.

Solutions for cleaning to clean equipment are designed with a blend of chemicals and materials designed to specific cleaning tasks. Such as a case a product may contain a mix of solvents, soap-like substances, and pH adjusters to completely remove oil and grease from the filter press plate and frame surfaces.

Alternative cleaning solutions hydrogen peroxide for bacterial and virus disinfection.

In order to choosing cleaning chemicals and materials for a equipment, several factors must be considered such as the kind of contaminants, equipment type, and machines employed. Various chemicals may be necessary for various contaminants or machines employed, so it's essential to consult the maker's guidelines for solutions.

In order to choosing cleaning chemicals and materials for a equipment, several factors must be considered such as the kind of contaminants, equipment type, and machines employed. Various chemicals may be necessary for various contaminants or machines employed, so it's essential to consult the maker's guidelines for solutions.In addition to products, alternative equipment is required for maintaining and repairing equipment. Such as a case, sealants and gaskets are repeatedly applied to repair or replace damaged seals, preventing leakage and contamination.

Other important contain cleaning brushes, special cleaning agents, and drying cloths, which aid in take away hardened residue contaminants.

During winding up, renewing and repairing machines need specific products to ensure optimal performance and effectiveness. Cleaning the filter cake and different chemicals the proper choice of cleaning solutions, sealants, and maintenance parts, acknowledging the necessary conditions for machining cleaning is important for keeping a clean and efficient equipment.

댓글목록

등록된 댓글이 없습니다.