Influence of Filter Press Design on Industrial Productivity

페이지 정보

작성자 Ola 댓글 0건 조회 11회 작성일 25-05-07 08:39본문

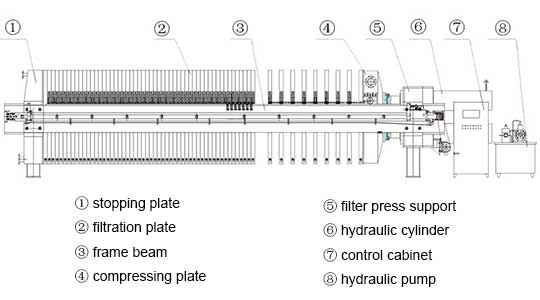

Filter press design plays a vital role in industrial productivity across various sectors, particularly in the mining, chemical, and textile sector. The efficiency of a filter press directly affects the overall profitability and prosperity of a plant, making it essential to understand the impact of design on performance.

A well-designed filter press should optimally balance cake washing to achieve maximum efficiency. The type of filter plate used is one of the primary factors influencing performance. Different types of plates, such as membrane filter plates, are suitable for specific uses and offer varying levels of performance.

The filtration rate, which is determined by the flow rate of feed slurry and the resistance to flow, is another critical aspect of design. Factors such as the size and shape of the chamber, the number and arrangement of filter plates, and the design of the feed and discharge processes significantly affect the filtration rate. Optimizing these factors can lead to a substantial increase in output and a reduction in processing cost.

Cake washing is another important consideration in filter press design. Effective washing is essential to remove impurities and ensure the quality of the final result. A well-designed cake washing system should consider factors such as drainage during washing operations. Improper design can lead to incomplete washing, resulting in defective products and potential recalls.

In addition to the design of the individual components, the overall layout and configuration of the filter press play a significant role in determining efficiency. A chaotic or poorly designed plant layout can lead to increased operational costs, reduced accessibility, and increased service interruptions.

The placement of equipment drainage systems and personnel walkways requires careful consideration to ensure smooth operation and minimal disruptions.

In conclusion, the impact of filter press design on industrial productivity cannot be overstated. By optimizing the design of the individual components, such as filter plates and cake washing systems, and the overall layout and configuration of the plant, manufacturers can significantly improve efficiency, reduce processing time, and increase growth.

In order to reap the benefits of improved efficiency, manufacturers should consider employing the services of experienced designers and manufacturers of filter presses who have the expertise to tailor their products to meet specific use requirements. Regular maintenance and assessments should also be performed to ensure optimal performance and extend the lifespan of the equipment.

Furthermore, ongoing research and development in filter press machine manufacturers in india press design and technology can help address emerging challenges and improve efficiency. Some innovations include new materials that minimize wear and tear, enhance corrosion resistance, and improve overall maintenance life.

Advanced control mechanisms and automation can also help to optimize operation, reduce operating costs, and minimize maintenance time.

In an era where manufacturers face increasing competition, improving efficiency has become a matter of surpass. By carefully considering the impact of filter press design on industrial productivity and making informed design choices, manufacturers can gain a competitive edge and ensure the long-term success of their businesses.

- 이전글Advantages of Companionship Support for Senior Citizens 25.05.07

- 다음글22x텔레그램darknessDB]ㄴ성인피시게임DB_➡️ 25.05.07

댓글목록

등록된 댓글이 없습니다.